MECAmaster Assembly is a Powerful and Robust Solution for 3D variation analysis within an assembly and the identification of the respective causes.

MECAmaster delivers the ability to simulate and analyse on geometrical requirements the final impact of the design choices and of the expected input tolerances on the components.

Based on a numerical model, MECAmaster requires very elementary information to work and is then very well adapted since the preliminary design. Giving the possibility to the designers to experience early in the process the concepts on the table will help them to always keep in mind the final geometrical quality of the product and then to get a Robust Design.

MECAmaster Assembly delivers for examples the ability to :

- experiment from a previous design the robustness of the assembly architecture …

- compute the 3D tolerance stack-ups and helps to define components dimensionnal and geometrical tolerances …

- statistically simulate virtual assemblies to estimate Non-Conformity Rates, etc …

- Simulate numerically the impact of real measured values before building the real assembly …

The identification of 3D variations, and their respective causes (Input Tolerances, Assembly Architecture … ) helps today many companies to work on a Robust Design.

-

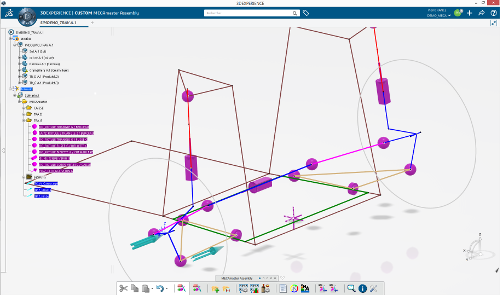

Architecture / Assembly Analysis

Architecture / Assembly Analysis

Objectives

- Compare Assembly concepts / configs from a preliminary design

- Decline the Assembly requirements to sub-assemblies requirements

How MECAmaster helps ?

Through easy interface definition & sensitivity analysis MECAmaster

gives some precious information about the geometrical robustness of

the assembly concept, from preliminary design. -

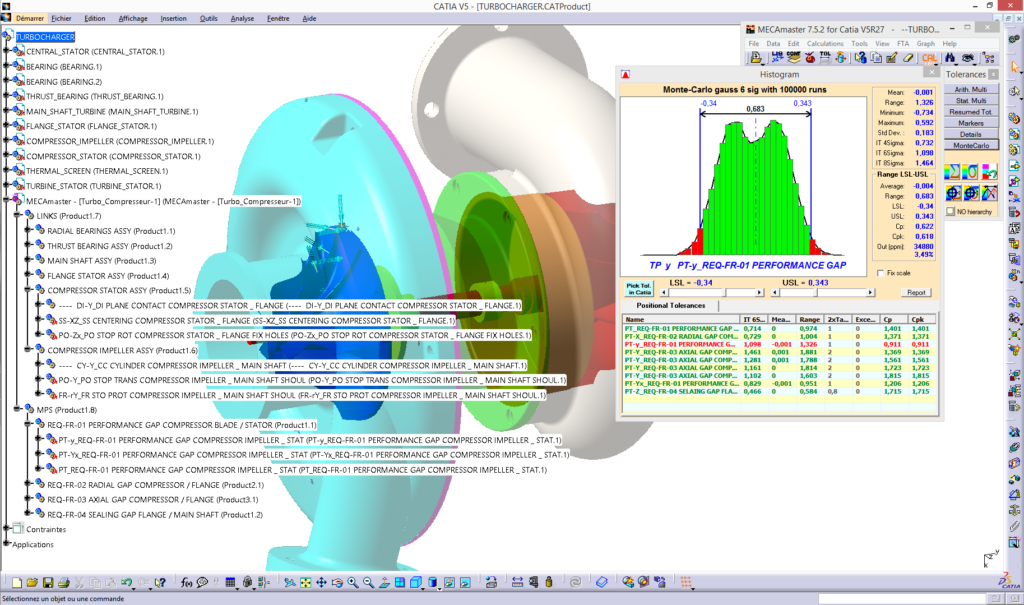

Detailled Design

Detailled Design

Objectives :

- Compute 3D tolerance Stack-ups taking into account technical design

principles and check requirements feasability

- Identify the main contributors to adjust GD&T Tolerances

How MECAmaster helps ?

MECAmaster computes resulting displacements using a Robust,

Numerical, 3D calculation taking into account all design principles

and GD&T defined tolerances -

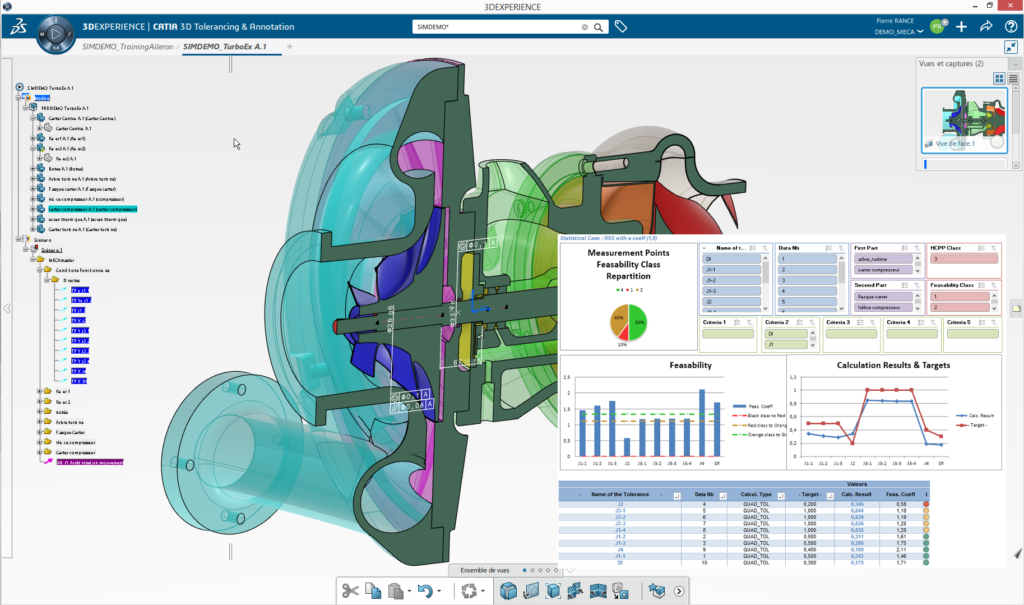

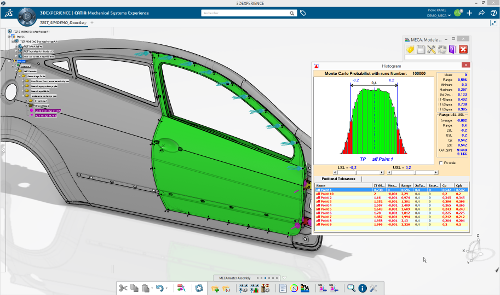

Statistical Validation

Statistical Validation

Objectives :

Simulate virtual assemblies associating basic statistical capability

information on input tolerances and estimate Non-Conformity ...

to adjust manufacturing process.

How MECAmaster helps ?

MECAmaster will build a very high number of virtual assemblies

taking into account statistical information given on input values

in a record time to get a full and wide population of results from

which will be extracted statistical information. -

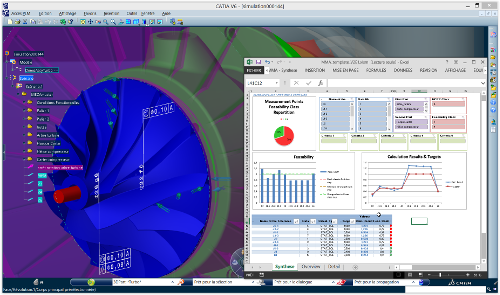

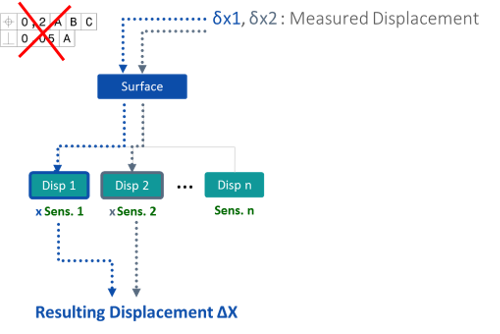

Real Values Integration

Real Values Integration

Objectives

Build a single virtual assembly involving real measured values

instead of previsional tolerances to anticipate adjustment needs.

How MECAmaster helps ?

MECAmaster delivers the ability to involve for each interface

a signed measured values instead of a previsional tolerance.

The calculation is based on the same model but this time giving

back a signed displacement instead of a range ...

- Optimal since solution analysis on preliminary design

- Full transparent and justified calculations

- Really high calculation speed even on very large assemblies

- Real Worst Case and not a simulation extremum

- Kinematical Evolution on the results

MECAmaster is today available in CATIA V5 and in 3DEXPERIENCE.

As MECAmaster has in charge all the sale process of MECAmaster software, kindly use the contact form of this site to get in touch with us !